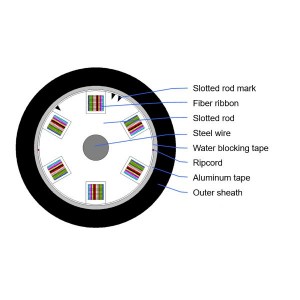

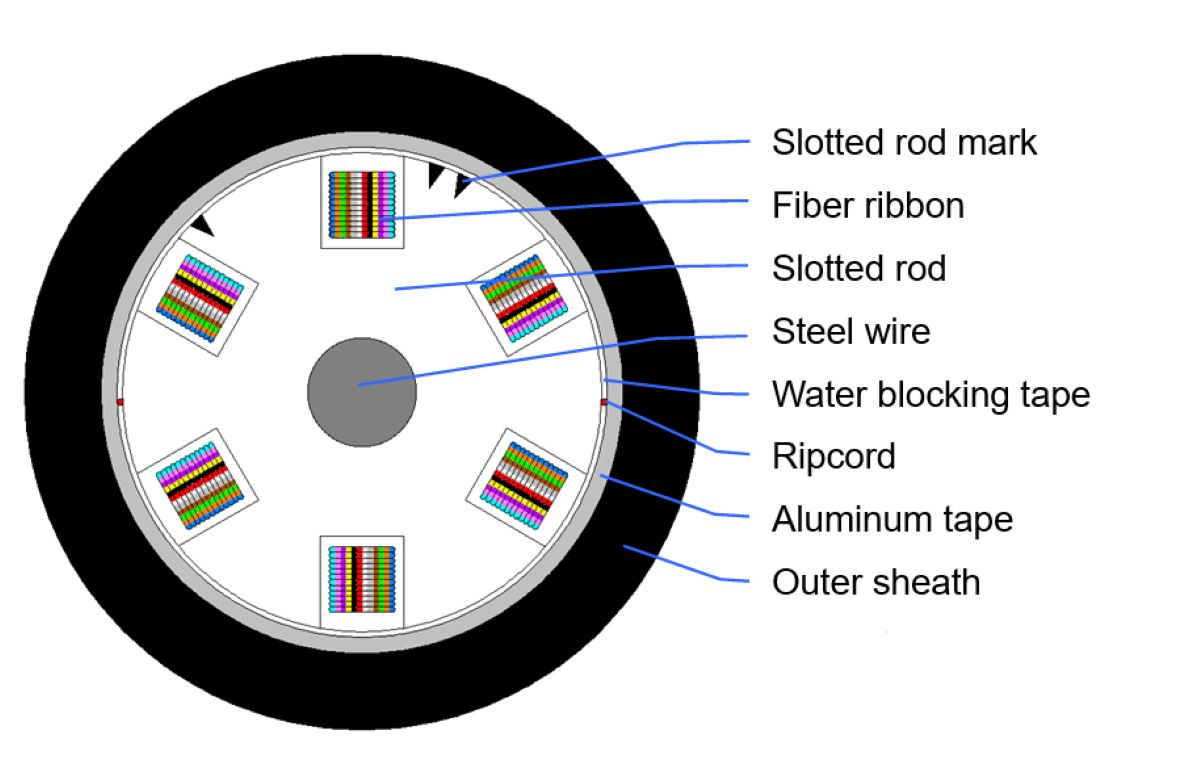

Slotted Ribbon Cable (GYDGA) Wasin Fujikura

Description

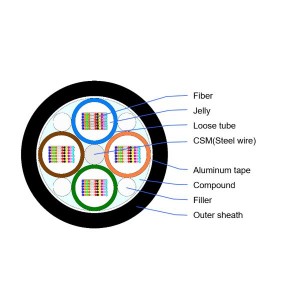

The fibers are placed parallel and cooted together.to form fiber ribbon. The fiber ribbons are housed in slots, which has a central strength member, to form the cable core. The core is wrapped with water-blocking tape and laminated aluminum tape longitudinally. Then a layor of polyethylene sheath is extruded.

Feature

*The cable provides excellent optical and mechanical performance with exclusively designed structure.

*The Gel-free Water Blocking technology improve efficiency of installation, and environment-friendly.

*High fiber density, and light in weight.

Suit for mass fusion splice

*Easy to mid-span after the cable is stripped.

*30 years of product life.

Performance

*Application:trunk network, access network

*Installation:Duct

*Operating Temperature:-40~+70℃

*Minimum Bending Radius:Operation: 10 x cable diameter

Installation: 20 x cable diameter

Structure and technical specifications

| Fiber

Count |

Noumber of frame slot | Maximum Fiber

Count of each fiber ribbon |

Nominal Diameler (mm) | Nominal Weight (kg/km) |

Allowable Tensile Load(N) (Short term/long term) |

Allowable Crush Resistance (N/10cm) (Short term/long term) |

|

| 4 Fiber Ribbon | 24 | 3 | 2 | 11.0 | 101 | 3000/1000 | 3000/1000 |

| 60 | 5 | 4 | 12.0 | 113 | 3000/1000 | 3000/1000 | |

| 100 | 5 | 5 | 13.7 | 144 | 3000/1000 | 3000/1000 | |

| 200 | 10 | 5 | 15.7 | 214 | 3000/1000 | 3000/1000 | |

| 300 | 15 | 5 | 20.3 | 322 | 3000/1000 | 3000/1000 | |

|

6 Fiber Ribbon |

72 | 3 | 4 | 12.6 | 140 | 3000/1000 | 3000/1000 |

| 96 | 4 | 4 | 12.6 | 140 | 3000/1000 | 3000/1000 | |

| 120 | 5 | 4 | 13.8 | 146 | 3000/1000 | 3000/1000 | |

| 144 | 6 | 4 | 14.2 | 155 | 3000/1000 | 3000/1000 | |

| 216 | 6 | 6 | 17.0 | 240 | 3000/1000 | 3000/1000 | |

| 288 | 8 | 6 | 17.7 | 258 | 3000/1000 | 3000/1000 | |

| 384 | 8 | 8 | 20.2 | 350 | 3000/1000 | 3000/1000 | |

| 432 | 9 | 8 | 21.2 | 378 | 3000/1000 | 3000/1000 |