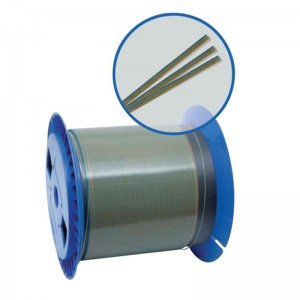

Optical Fiber Ribbon Wasin Fujikura

description

Optical fiber ribbons are often used in high fiber count cables. Nanjing Wasin Fujikura optical fiber ribbon become customer the first selection due to its low-loss performance and stability Dimension. Wasin Fujikura could provide side pressure resistant 8-core embeded optical fiber ribbon , and 16-core, 24-core, 36-core embeded high fiber count optical fiber ribbon, mainly applied to Slotted Core Optical fiber cable and high fiber count optical cable, and accepts customized ribbons according to customer's requirements.

The main difference between optical fiber access network optical cable and trunk optical cable is that the number of optical fibers in access network optical cable is more larger, usually from dozens to hundreds of cores, and then up to thousands of cores. For optical cables with a large number of cores, two problems are required to be solved. One is that the optical fiber density in the optical cable should be large to limit the volume of the optical cable. The second is to solve the problem of simple optical fiber connection, so as to save the engineering cost. Therefore, the adoption of ribbon optical cable can well solve the above two problems.

Generally, the ribbon optical cable is divided into two structural forms: one is bundle tube type, and the bundle tube ribbon optical cable is divided into central bundle tube type and layer twisted type. The second is the skeleton type. The skeleton ribbon optical cable also has a variety of structural forms of single skeleton and composite skeleton. The two optical cables have their own characteristics and application environments are slightly different.

One common feature of all these ribbon optical cables is that several optical fiber bands are stacked and placed in the bundle tube or skeleton slot, so as to ensure a high density of optical fibers in the optical cable. Ribbon optical cable is widely used in the environment of large core optical fiber ring of urban area network and backbone optical cable of access network, which plays an important role in realizing optical fiber to community (or roadside, building and unit).

performance

| DimensionMaximum | Number of cores | bandwidth (nm) | thickness (nm) | Core distance (nm) | Planeness(nm) | |

| 4 | 1220 | 400 | 280 | 35 | ||

| 6 | 1770 | 400 | 300 | 35 | ||

| 8 | 2300 | 400 | 300 | 35 | ||

| 12 | 3400 | 400 | 300 | 35 | ||

| 24 | 6800 | 400 | 300 | 35 | ||

| Optical | Adding attenuation | |||||

| performance | 1550nm less than 0.05dB/km | |||||

| Other optical performance accord with the nationally standard | ||||||

| Environmental performance | Temperature Dependence | -40 〜+70°C, adding attenuation not more than 0.05dB/ km in 1310nm wavelength and 1550nm wavelength, | ||||

| Dry heat | 85±2 °C , 30days, adding attenuation not more than 0.05dB/km in 1310nm wavelength and 1550nm wavelength. | |||||

| Mechanical | twisting | twist 180°in 50cm long, no damage | ||||

| performance | separation property | Separate fiber ribbon with min 4.4N force, colour fiber no damage, colour mark vivid in 2.5cm length | ||||