Non-metallic strength member, loose tube stranded cable with inner PE sheath and steel tape armored outer PE sheath (GYFTY53) Wasin Fujikura

Description

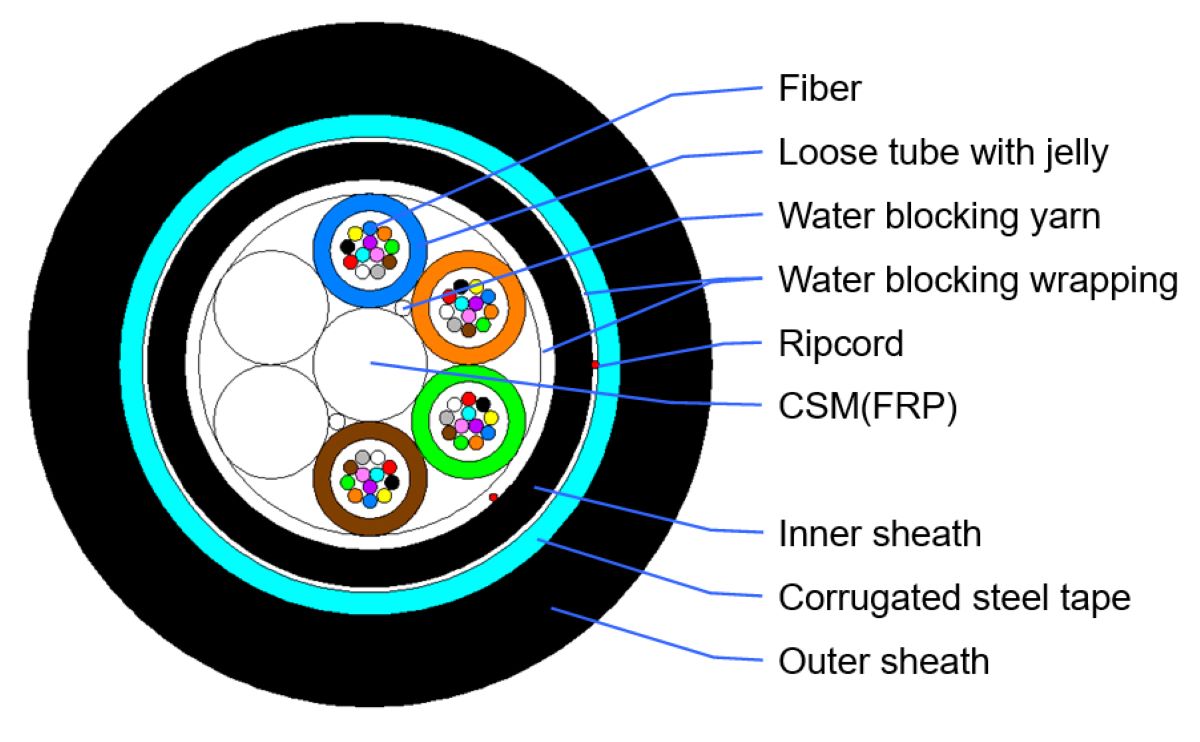

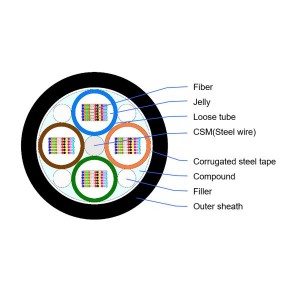

The fibers are positioned in loose tubers made of high modulus plastic. The tubes are filled with water-blocking compound. The dielectric fiber reinforced plastic rod, coated with polyethylene if necessary, locates in the center of core as the strength member. Tubes are stranded around the strength member to form the cable core. A layer polyethylene is extruded as inner sheath. After the PSP is longitudinally applied over the inner sheath, the cable is complete with PE outer sheath.

Feature

All selection water blocking construction, provide good performance of moisture-proof and water block;

Special filling gel filled loose tubes provide perfect optical fiber protection

High young’s modulus reinforce plastic (FRP) as central strength member.

Longitudinal corrugated steel tape armored provides reliable performance of moisture-proof and gives desirable crush resistance.

FRP central strength member is applicable to frequently lighting areas.

Strict craft and raw material control enable lifespan over 30 years.

Performance

Application: long haul and building network communication;

Installation: duct/aerial;

Operating temperature: -40~+70℃;

Bending radius: static 10*D/ Dynamic25*D.

Structure and technical specifications

| Fiber count | Nominal diameter (mm) |

Nominal weight (kg/km) |

Max fiber per tube | NO.OF(Tubes +filler) | Allowable tensile load (N) (short term/long term ) |

Allowable crush resistance (N/10cm) (short term/long term ) |

|

2~42 |

14.1 |

193 |

6 |

7 |

2700/1000 |

3000/1000 |

|

44~72 |

15.1 |

212 |

12 |

6 |

2700/1000 |

3000/1000 |

|

74~96 |

16.3 |

246 |

12 |

8 |

2700/1000 |

3000/1000 |

|

98~120 |

17.8 |

288 |

12 |

10 |

3000/1000 |

3000/1000 |

|

122~144 |

19.4 |

336 |

12 |

12 |

3000/1000 |

3000/1000 |

|

>144 |

Available upon customer’s request |

|||||