Why should we pursue lean?

In recent years, the competition in the optical fiber and cable industry tends to be white-hot, and the operating pressure of various manufacturers is increasing, whether it is cost optimization at the production end or service initiatives at the market end. In order to continue to maintain market competitiveness, the company has carried out continuous exploration and reform in improving the management environment, enhancing operational efficiency, and breaking through bottlenecks, and the concept of lean production and lean management has gradually taken root in the company.

What have we done about it?

Since 2021, the company has independently carried out relevant lean project promotion work with the support of leaders through the learning of friends and the lean project experience of the department. However, due to the lack of systematic guidance and professional tools, the depth and breadth of various work promotion are insufficient, and a good self-drive atmosphere has not been formed.

What are we doing about it?

In order to carry out lean project management work more systematically and efficiently, this month we specially invited the lean management team of Appleway to train and guide our company.

At the beginning of the meeting, Zhang Guangping, deputy general manager of the company, introduced the background of this lean management project. The company’s implementation of lean project management is to build a solid foundation for development and actively respond to the needs of market competition. Lean production will also be the top priority of the company in the first phase of this lean project. Minimize waste.

Lean from the heart, to change the thinking, old and new, the introduction of new ideas, with lean thinking mode to constantly improve the overall company’s operating efficiency.

What is our goal?

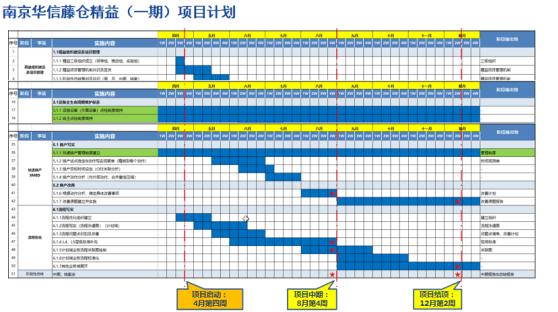

Yuan Ye, the leader of the Lean project team, explained the plan and explained the specific implementation plan for the Lean phase I project of Nanjing Huaxin Fujikura, which was divided into five parts: on-site 6S& visual management, TPM professional security, team management, SMED and process optimization.

What do we need to do?

Li Wei, general manager of Nanjing Huaxin Fujicang, put forward five requirements for lean work. First, get your attitude right. Identify from the heart, input, let lean into the work, believe in the power of lean, accept innovation; Second, switch roles. Lean work with zero apprentice mentality to continuously improve our manufacturing management level; Third, be willing to endure hardships. Any change and improvement will make us temporarily out of the comfort zone, we must overcome the fear of difficulties on the basis of recognition, and benefit from improvement; Fourth, be persistent. Do not put lean change in a mere form, persevere in lean into the work; Fifth, seek truth from facts. Tell the truth and do the real thing. Our ultimate goal is to strive to make Nanjing Huaxin Fujikura become specialized in various special fields.

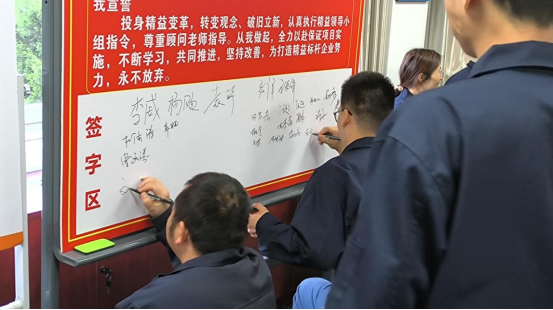

Then, under the leadership of General manager Li Wei, the pledge and signature of the lean project launching meeting, the oath is strong and strong, which fully reflects the determination and confidence of all colleagues in Nanjing Huaxin Rattan Warehouse for the implementation of this lean management project.

The Lean management project launch conference has come to a successful end, and it is also the beginning of Nanjing Huaxin Tengcang Company’s systematic promotion of lean management project. I believe that under the guidance of the teachers of the precision project team and the joint efforts of all employees, we will sort out lean concepts, cultivate lean thinking, practice lean methods and tools, focus on improving quality and efficiency, accurately match standards, and stimulate innovation vitality. And then enhance the core competitiveness of the company.

Post time: May-31-2024