Micro module cable (GYFBY) Wasin Fujikura

Description

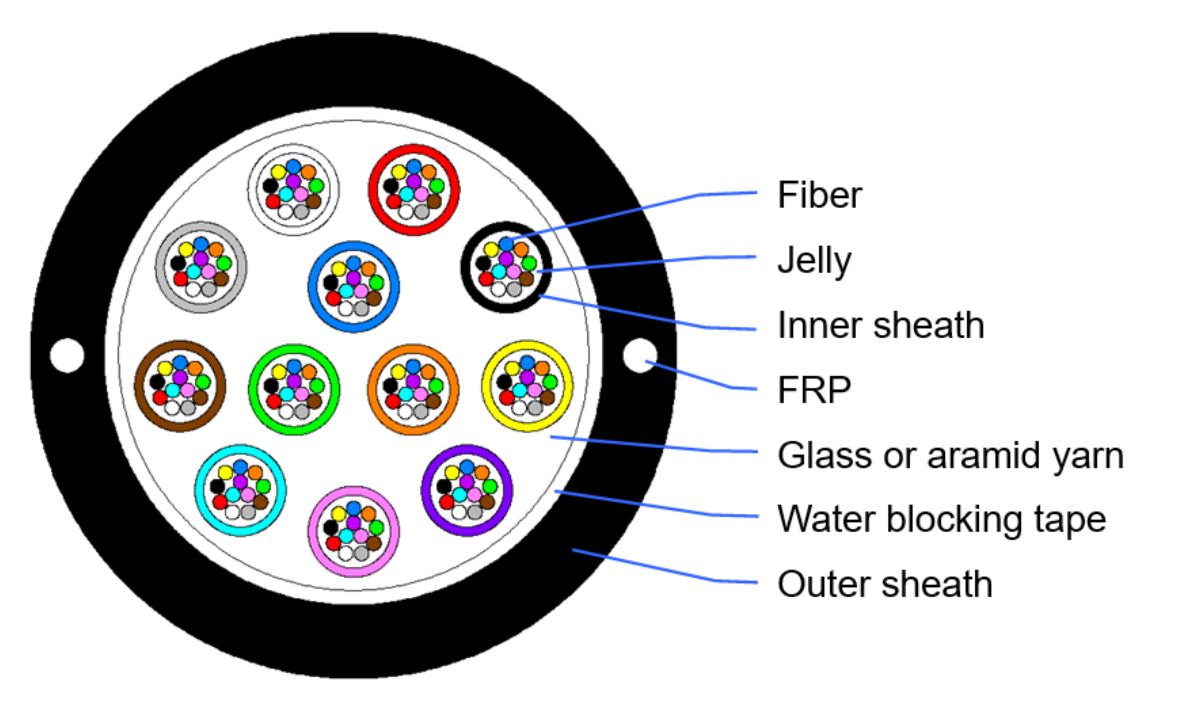

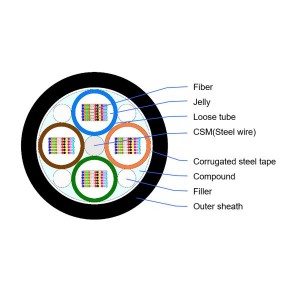

The fibers, are positioned in a loose tube made of flexible material. The tube inside are filled with a water-resistant filling compound. Multi tube strand together in certain pitch .High strength material such as glass yarn are used as additional strength member. Two paralleled FRP are placed at the two side of the core. Outside the core and strength members, the polyethylene sheath is extruded to provide the UV resistance .

Feature

Small diameter, high fiber density

Semi-dry water blocking

Perfect cable structure

The tube sheath can be removed by finger easily

Saving the source of duct

Performance

Application: long haul and building network communication;

Installation: duct, aerial ;

Operating temperature: -40~+70℃;

Bending radius: static 10*D/ Dynamic25*D.

Structure and technical specifications

|

FIBERS PER TUBE |

CORES |

CABLE DIAMETER (Appr.) |

MAX TENSION |

CABLE WEIGHT |

OUTER COLOR |

|

12 |

12 |

8.4mm |

2200N |

54kg/km |

Black |

|

12 |

24 |

8.8mm |

2200N |

59kg/km |

Black |

|

12 |

36 |

9.1mm |

2200N |

64kg/km |

Black |

|

12 |

48 |

9.5mm |

2200N |

67kg/km |

Black |

|

12 |

72 |

10.2mm |

2200N |

77kg/km |

Black |

|

12 |

144 |

11.8mm |

2700N |

104kg/km |

Black |

|

12 |

288 |

14.5mm |

3000N |

150kg/km |

Black |