Metallic strength member loose tube stranded fiber ribbon cable with steel tape armored PE sheath (GYDTS) Wasin Fujikura

Description

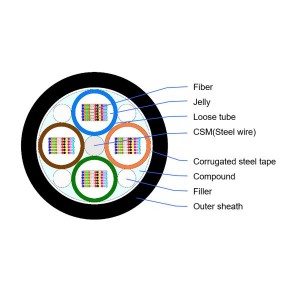

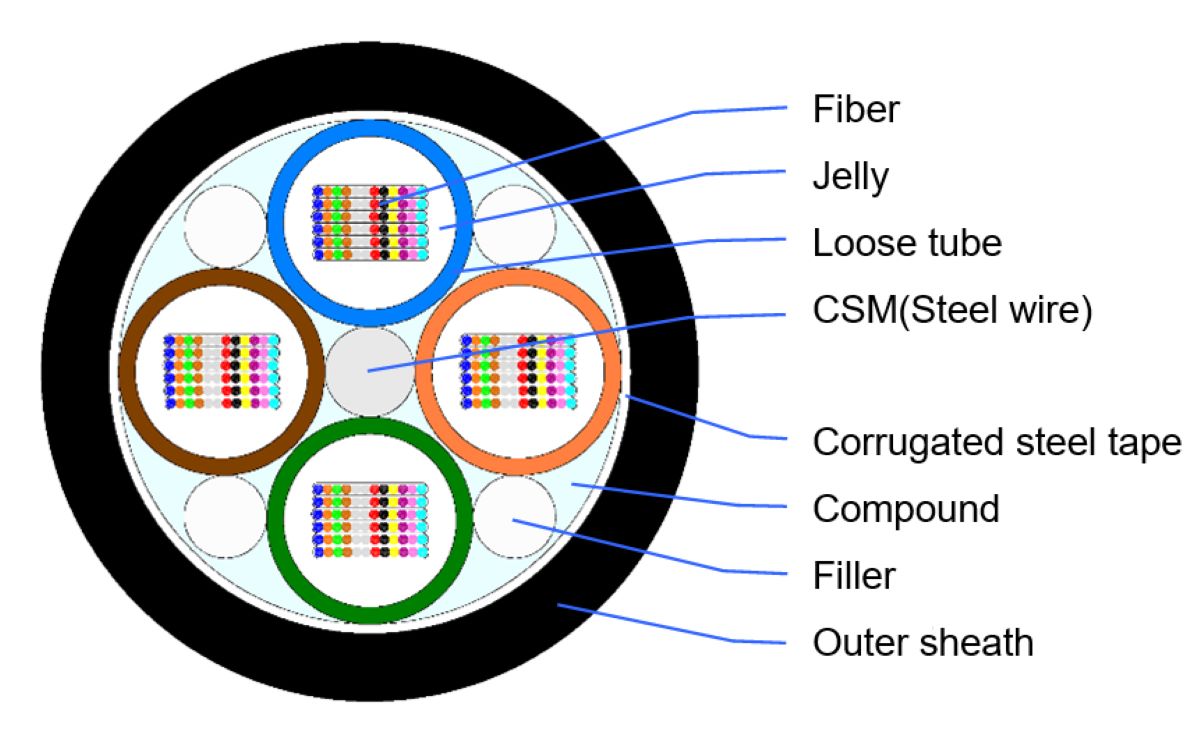

The fiber ribbons, are positioned in a loose tube made of a high modulus plastic. The interstice inside and outside of the tubes are filled with a water-resistant filling compound. A steel wire, coated with polyethylene if necessary locates in the center of core as a strength member. Tubers (and fillers) are stranded around the strength member to form a compact and circular cable core. The plastic coated steel tape is wrapped over the core and extruded into a polyethylene sheath to form a cable.

Feature

Full section water blocking construction, provide good performance of moisture-proof and water resistance;

Special filling gel filled loose tubes provide perfect optical fiber protection.

Corrosion resistance phosphate steel wire with high modulus as central strength member.

High fiber density, convenient for installation, easy identification and maintenance, cost saving.

The flexible buffer tubes are easily to route in closures.

Excellent mechanical and temperature performance.

Jacket provide superior protection against UV radiation, fungus, ,abrasion and other environmental factors.

Strict craft and raw material control enable lifespan over 30 years.

Performance

Application: Access network and building network communication

Installation: Duct/Aerial

Operating Temperature: -40~+70℃

Bending Radius; Static 10 x D / Dynamic 20 x D

Structure and technical specifications

|

Fiber Count |

No. of |

Max Ribbonrs Per Tube |

Nominal Diameler (mm) |

Nominal Weight (kg/km) |

Allowable Tensile Load(N) (Short term/long term) |

Allowable Crush Resistance(N/10cm) (Short term/long term) |

|

|

6-Fiber Ribbon |

12~120 |

5 |

4 |

16.6 |

271 |

1500/600 |

1000/300 |

|

126~180 |

5 |

6 |

16.6 |

271 |

|||

|

186~288 |

6 |

6 |

20.4 |

414 |

2200/600 |

||

|

12-Fiber Ribbon |

24~192 |

4 |

4 |

17.8 |

300 |

2200/600 |

1000/300 |

|

204~288 |

4 |

6 |

18.6 |

336 |

|||

|

300~360 |

5 |

6 |

20.4 |

387 |

|||

|

372~432 |

4 |

9 |

22.0 |

474 |

|||

|

432~576 |

5 |

12 |

23.5 |

550 |

|||

| >600 |

Available upon customer’s request |

||||||

Special cable structure can be designed and manufactured on customer's request.