Loose tube stranded armored figure 8 self-supporting aerial cable (GYTC8S) Wasin Fujikura

Description

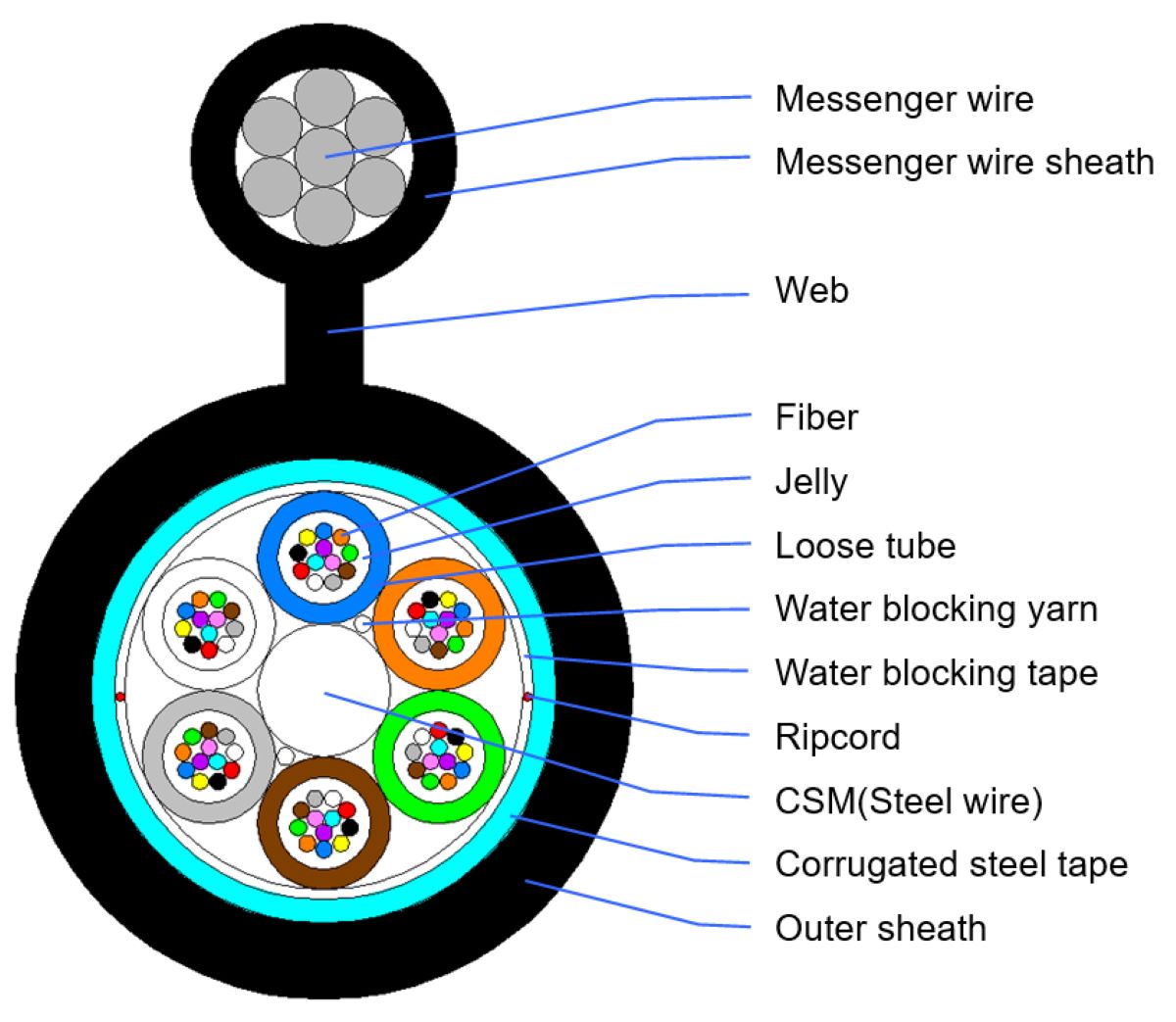

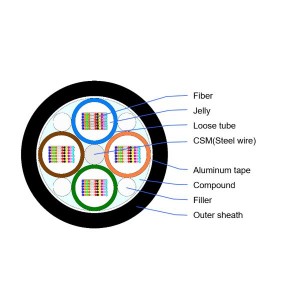

The fibers, are positioned in a loose tube made of a high modulus plastic. The interstice inside and outside of the tubes are filled with a water-resistant filling compound. A steel wire, coated with polyethylene if necessary locates in the center of core as a strength member. Tubers (and fillers) are stranded around the strength member to form a compact and circular cable core. The plastic coated steel tape is wrapped over the core and extruded into a polyethylene sheath to form a cable. The galvanized steel stranding wires is applied as the messenger. Finally, the messenger and the cable is linked together to form type figure -8 cable..

Feature

All section water blocking provides reliable performance of moisture-proof and water block.

Special filling gel filled loose tube provide perfect optical fiber protection.

Longitudinal corrugated steel tape gives desirable crush resistance.

Figure 8 self-supporting structure presents high tensile strength and enables easy and cost saving aerial installation.

Strict craft and raw material control enable lifespan over 30 years.

Performance

Application:Long haul and building network communication

Installation:Self-supporting aerial

Operating Temperature:-40~+70℃

Steel Messenger:1.2×7、1.5×7

Bending Radius:Static 10×D/Dynamic 20×D

Structure and technical specifications

|

Fiber Count |

Nominal Diameter |

Nominal Weight |

Max Fibers Per Tube |

No. of (Tubes + Fillers) |

Allowable Tensile Load(N) |

Allowable Crush Resistance(N/10cm) |

|

2~30 |

10.0×18.0 |

220 |

6 |

5 |

7000/4000 |

1000/300 |

|

32~36 |

10.7×18.7 |

244 |

6 |

6 |

7000/4000 |

1000/300 |

|

38~60 |

11.4×19.4 |

253 |

12 |

5 |

7000/4000 |

1000/300 |

|

62~72 |

12.0×20.0 |

280 |

12 |

6 |

7000/4000 |

1000/300 |

|

>72 |

Available upon customer’s request |

|||||