Loose tube stranded air-blown micro cable (GCYFTY) Wasin Fujikura

Description

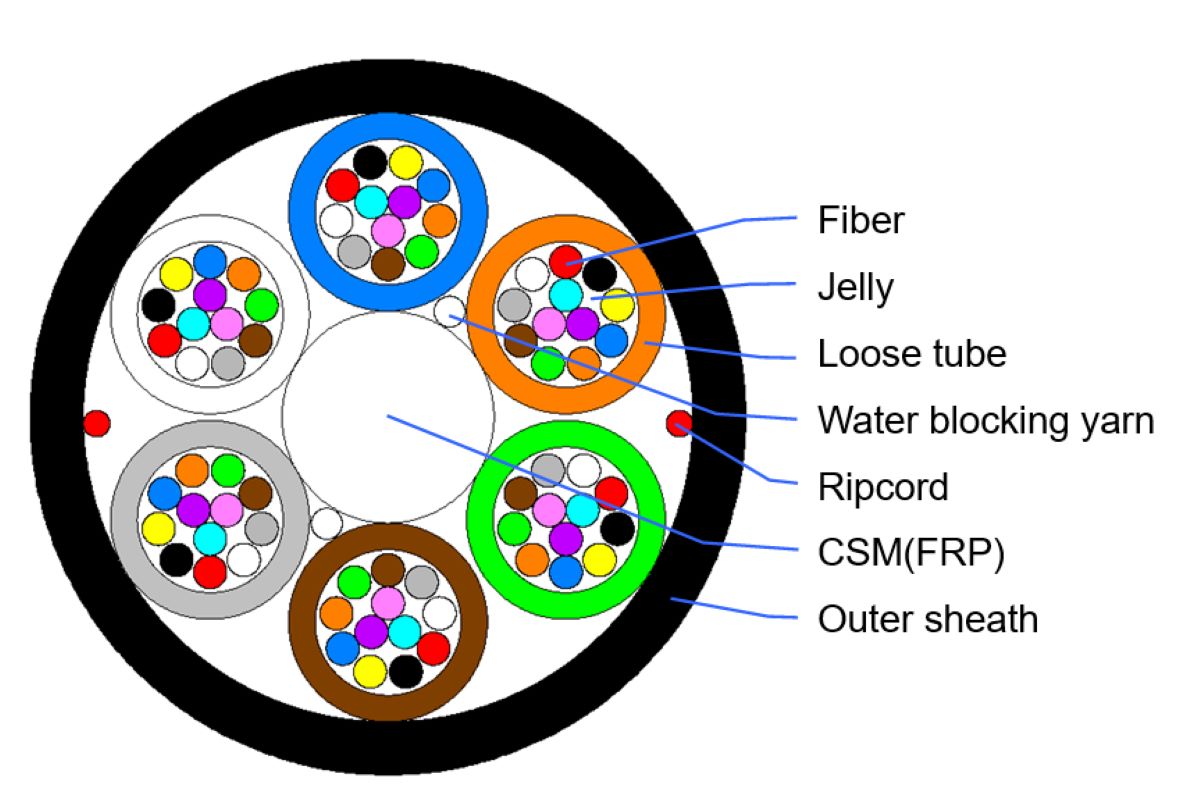

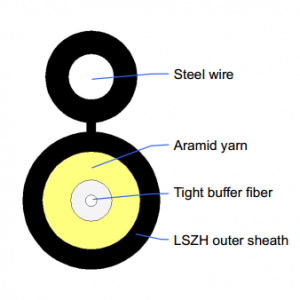

The fibers, are positioned in a loose tube made of a high modulus plastic filled with jelly . A fiber reinforced plastic rod(FRP), coated with polyethylene if necessary locates in the center of core as a strength member. Tubers (and fillers) are stranded around the strength member to form a compact and circular cable core. A layer of thin polyethylene sheath is extruded around the cable core to form a cable.

Feature

Small size, light weight, high fiber density

Suitable for air-blown installation

Excellent temperature performance for different temperature environment application.

Performance

Application: long haul and building network communication;

Installation: duct;

Operating temperature: -40~+70℃;

Bending radius: static 10*D/ Dynamic20*D.

Structure and technical specifications

|

Fiber Count |

Nominal

Diameter (mm) |

Nominal

Weight (kg/km) |

Allowable Tensile(N) | Minimum Bending

Radius(mm) |

Allowable Crusl Resistant(N/10cm) | ||

| Short term | Long term | Dynamic | Static | ||||

| 2~72 | 5.4 | 26 | 0.3G | 1G | 20D | 10D | 500 |

| 96 | 6.3 | 38 | 0.3G | 1G | 20D | 10D | 500 |

| 144 | 8.0 | 37 | 0.3G | 1G | 20D | 10D | 500 |

| 192 | 10.0 | 60 | 0.3G | 1G | 20D | 10D | 500 |

| 216 | 10.0 | 60 | 0.3G | 1G | 20D | 10D | 500 |

| 288 | 10.6 | 78 | 0.3G | 1G | 20D | 10D | 500 |

Special cables structures can be designed and manufactured on customer’s request