High Quality Outdoor Telephone Cable Suppliers - Electronic Cable- Composite Overhead Ground Wire With Optical Fibers (OPGW) – Wasin Fujikura Wasin Fujikura

High Quality Outdoor Telephone Cable Suppliers - Electronic Cable- Composite Overhead Ground Wire With Optical Fibers (OPGW) – Wasin Fujikura Detail:

introduction

► OPGW or known as Optical Ground Wire is a type of cable structure with composite of optical transmission and overhead ground wire for power transmission. It’s used in power transmission lines both as optical fiber cable and overhead ground wire which can provide protection of lightning strike and conducting short circuit current.

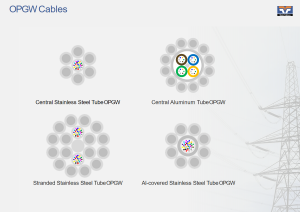

► The OPGW consist of stainless steel tube optical unit, aluminum cladding steel wire, aluminum alloy wire. It has central stainless steel tube structure and layer stranding structure. We can design the structure according to different environment condition and customer’s requirements.

Feature

► Stainless-steel optical fiber unit of central loose tube or layer stranding structure

► Aluminum alloy wire and aluminum clad steel wire armored

► Coated with anticorrosive grease between layers

► OPGW can support heavy load and long span installation

► OPGW can meet the ground wire’s requirement of mechanical and electric by adjusting proportion of steel and aluminum.

► Easy to produce the similar specification of exist ground wire can replace the exist ground wire.

► OPGW provides Power Companies an opportunity to use their towers for other purpose than power transmission. They for a small investment can provide Extremely High Capacity Links to the Telecom sector.

Application properties

► OPGW cable is run, or installed between the tops of high-voltage electricity pylons, steel, wood, or concrete poles with appropriate fittings and attachments. The conductive part of the cable, in this case the steel serves to bond adjacent towers to earth ground, and shields the high-voltage conductors from lightning strikes.

► OPGW have the characteristic that there is no effect of high voltage induction on the data being transmitted through the Fibers. Hence this characteristic of the Fiber is taken into advantage to transmit the data along the high power transmission lines.

► Optical fibers within the cable can be used for high-speed transmission of data. The electrical utility could use the fiber optics cable for its SCADA, protection and control system of the transmission line, VOIP, and other communication purposes. In such cases, they could save on the cost of installing additional steel wires serving as ground or shield wires to their lines. They could also lease or sold to third parties to serve as a high-speed fiber optic communication interconnection between cities, and other networks.

Structure and technical specifications

| Cable model | OPGW-60 | OPGW-70 | OPGW-90 | OPGW-110 | OPGW-130 |

| Number /diameter(mm) of stainless steel tube | 1/3.5 | 2/2.4 | 2/2.6 | 2/2.8 | 1/3.0 |

| Number /diameter of AL wire(mm) | 0/3.5 | 12/2.4 | 12/2.6 | 12/2.8 | 12/3.0 |

| Number /diameter of ACS wire(mm) | 6/3.5 | 5/2.4 | 5/2.6 | 5/2.8 | 6/3.0 |

| Diameter of Cable (mm) | 10.5 | 12.0 | 13.0 | 14.0 | 15.0 |

| RTS(KN) | 75 | 45 | 53 | 64 | 80 |

| Cable weight (kg/km) | 415 | 320 | 374 | 432 | 527 |

| DC resistance(20°C Ω/km) | 1.36 | 0.524 | 0.448 | 0.386 | 0.327 |

| Modulus of elasticity(Gpa) | 162.0 | 96.1 | 95.9 | 95.6 | 97.8 |

| coefficient of Linear thermal expansion (1/°C ×10-6 | 12.6 | 17.8 | 17.8 | 17.8 | 17.2 |

| Short circuit capacity (kA2s) | 24.0 | 573 | 78.9 | 105.8 | 150.4 |

| Max. operation temperature (°C) | 200 | 200 | 200 | 200 | 200 |

| Max. fiber count | 48 | 32 | 48 | 52 | 30 |

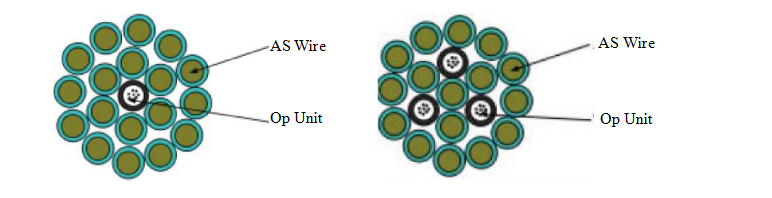

Typical Structure

► Type 1. Central stainless steel tube structure

► Type 2. Layer stranding structure

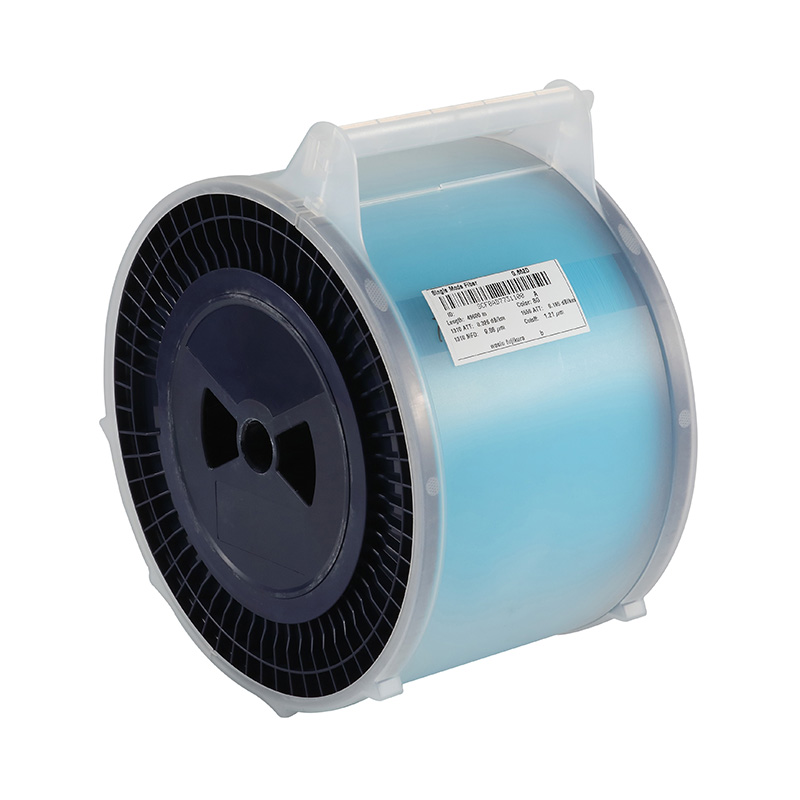

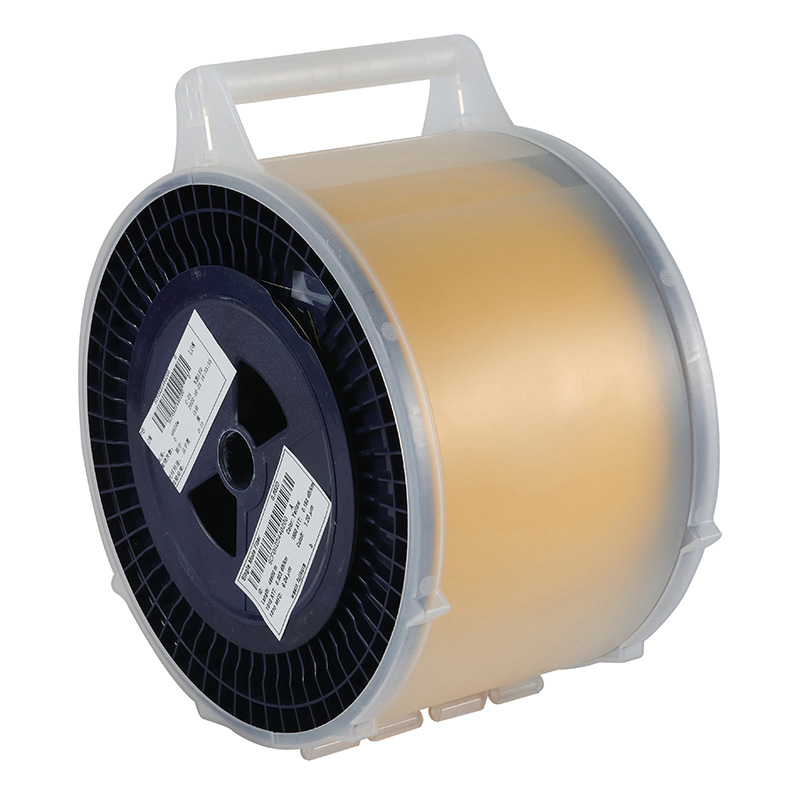

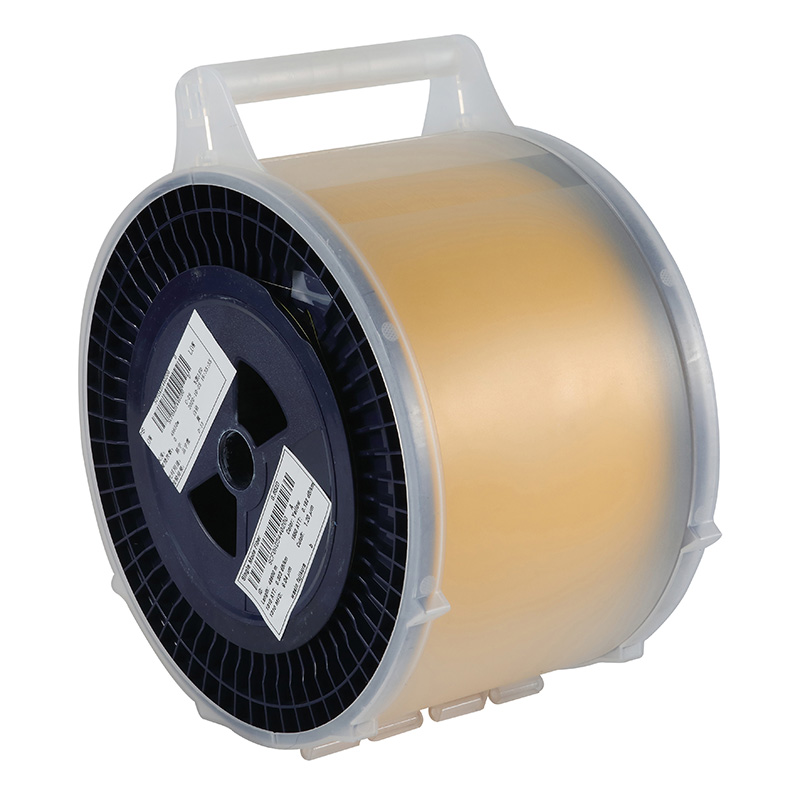

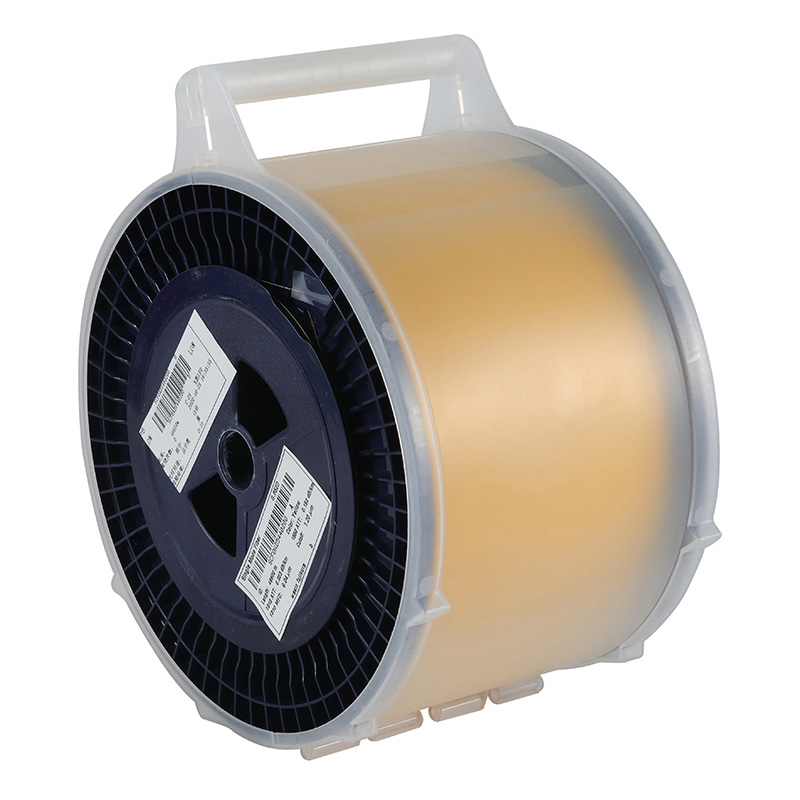

Product detail pictures:

Related Product Guide:

We have advanced equipment. Our products are exported to the USA, the UK and so on, enjoying a good reputation among customers for High Quality Outdoor Telephone Cable Suppliers - Electronic Cable- Composite Overhead Ground Wire With Optical Fibers (OPGW) – Wasin Fujikura , The product will supply to all over the world, such as: Mecca, Washington, Canada, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.