China wholesale Outdoor Fiber Optic Cable Manufacturers – Outdoor Cable Series- Loose Tube Stranded Cable With Aluminum Tape and Steel Tape Armored Double PE Sheath (GYTA53) – Wasin Fujikura Wasin Fujikura

China wholesale Outdoor Fiber Optic Cable Manufacturers – Outdoor Cable Series- Loose Tube Stranded Cable With Aluminum Tape and Steel Tape Armored Double PE Sheath (GYTA53) – Wasin Fujikura Detail:

description

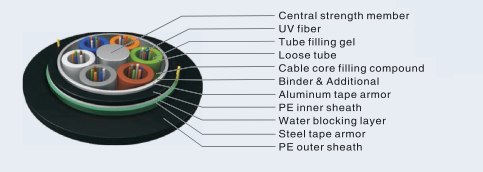

► Central strength member

► Loose tube stranded;

► Aluminum tape armored PE inner sheath

► Corrugated steel tape armored outdoor cable

► PE outer sheath outdoor cable

Performance

► Application: long haul and building network communication;

► Installation: duct/aerial;

► Operating temperature: -40-H-70 °C;

► Bending radius: static 10*D/ Dynamic25*D.

Feature

► All selection water blocking construction, provide good performance of moisture-proof and water block;

► Special filling gel filled loose tubes provide perfect optical fiber protection

► Corrosion resistance phosphate steel wire with high modulus as central strength member

► Longitudinal corrugated aluminum tape and steel tape gives desirable crush resistance.

► Strict craft and raw material control enable lifespan over 30 years.

► For flame retardant cable, outer sheath can be made of low-smoke zero halogen (LSZH) material, and the type is GYFTZA53, additional Nylon resin is extruded over the outer sheath and the type is GYFTA54.

► On customer’s requests, longitudinal color strip on outer sheath can be provided. More details please refer to GYTA series.

► Special cables structures can be designed and manufactured on customer’s request.

Structure and technical specifications

| Fiber count | Nominal diameter(mm) | Nominal weight (kg/km) | Max fiber per tube | NO.OF(Tubes+filler) | Allowable tensile load (N)(short term/long term) | Allowable crush resistance (N/l0m) (short term/long term) | |

| 2~36 | 13.9 | 202 | 6 | 6 | 3000/1000 | 3000/1000 | |

| 38~72 | 15.1 | 241 | 12 | 6 | 3000/1000 | 3000/1000 | |

| 74~96 | 17.1 | 290 | 12 | 8 | 3000/1000 | 3000/1000 | |

| 98~120 | 18.6 | 333 | 12 | 10 | 3000/1000 | 3000/1000 | |

| 122~144 | 20.2 | 381 | 12 | 12 | 3000/1000 | 3000/1000 | |

| >144 | Available upon customer’s request | ||||||

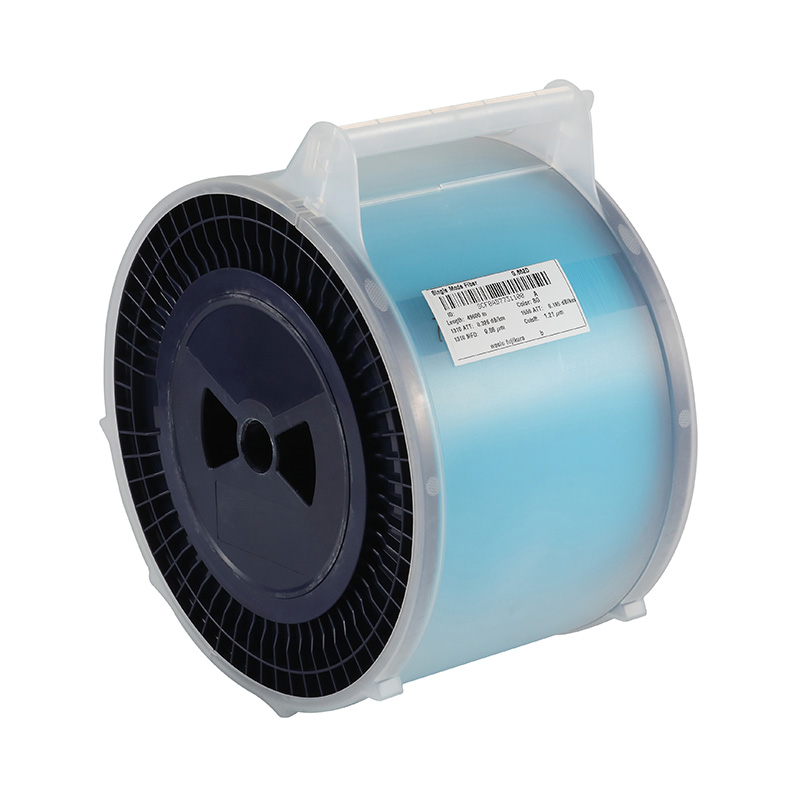

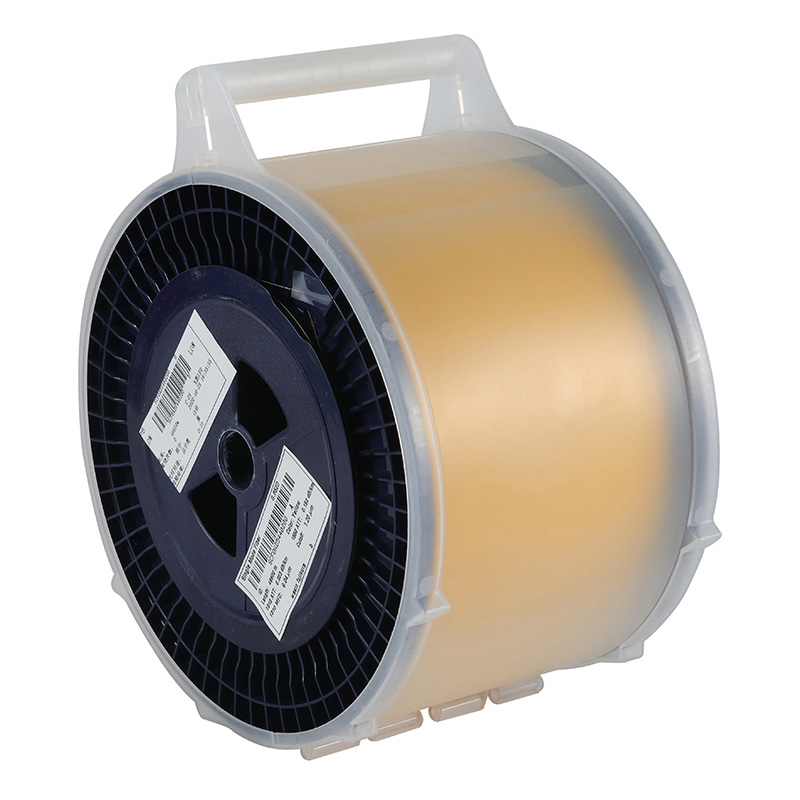

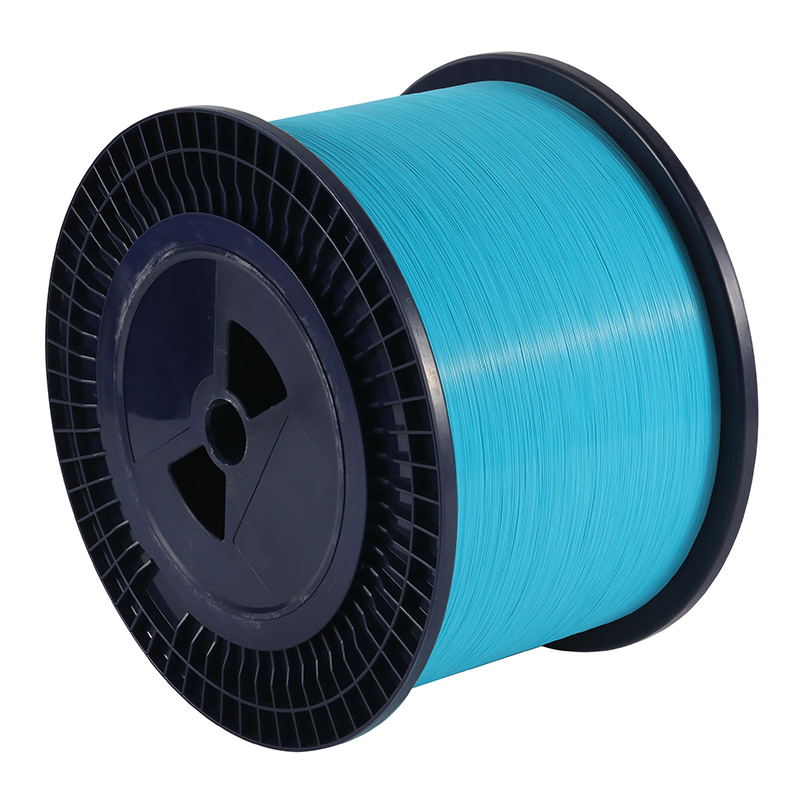

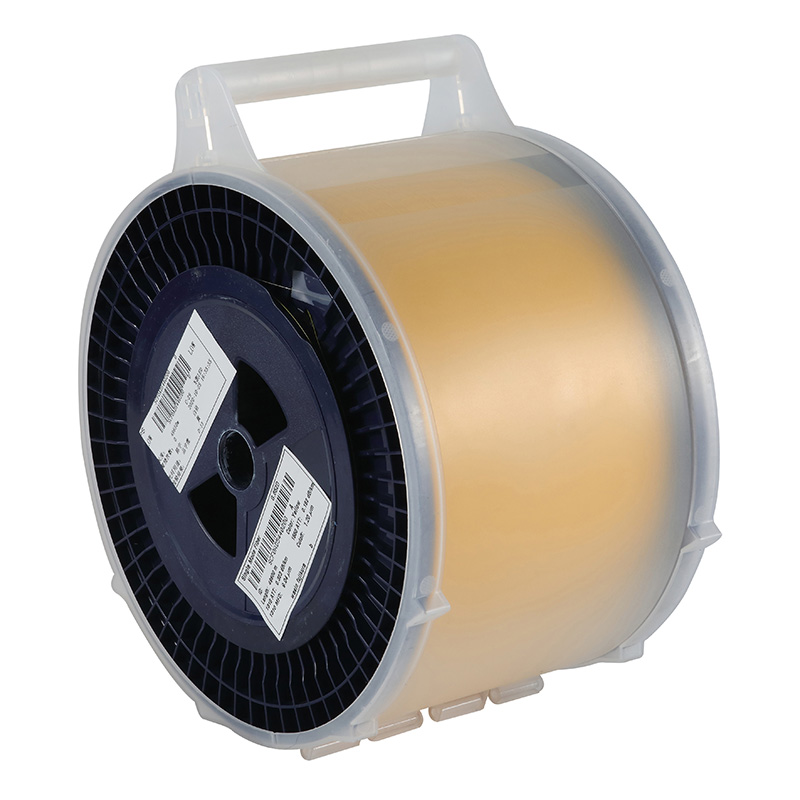

Product detail pictures:

Related Product Guide:

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for China wholesale Outdoor Fiber Optic Cable Manufacturers – Outdoor Cable Series- Loose Tube Stranded Cable With Aluminum Tape and Steel Tape Armored Double PE Sheath (GYTA53) – Wasin Fujikura , The product will supply to all over the world, such as: Sri Lanka, Morocco, Ireland, We've got sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.