Central tube fiber ribbon cable with paralleled steel wire strength (GYDXTW) Wasin Fujikura

Description

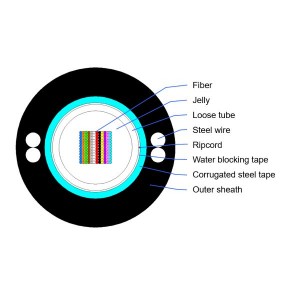

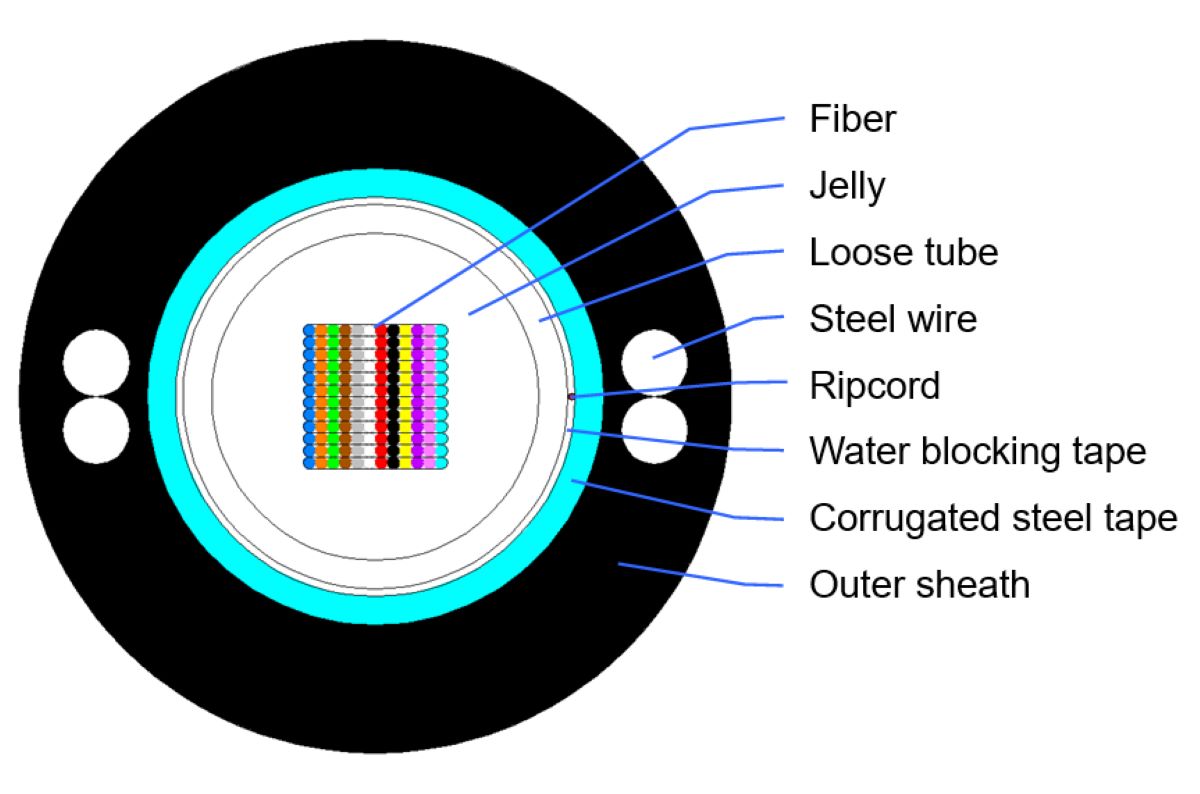

The fiber ribbons, are positioned in a loose tube made of a high modulus plastic. The tube is filled with a water-resistant filling compound. The tube is wrapped with one layer of coated steel tape longitudinally. Two paralleled steel wires are placed at the two sides of the steel tape. Outside the tube and strength members, the polyethylene sheath is extruded to provide the UV resistance

Feature

Full section water blocking construction, provide good performance of moisture-proof and water blocking

Special filling gel filled loose tubes provide perfect optical fiber protection.

Two parallel steel wires provide desirable tensile strength and crush resistance.

Suitable for access network (especial in FTTC and FTTB) interoffice connection and CATV network

High fiber density, convenient for installation, easy identification and maintenance, cost saving.

Strict craft and raw material control enable lifespan over 30 years.

Performance

Application :Access network and building network communication

Installation:Duct/Aerial

Operating Temperature:-40~+70℃

Bending Radius:Static 10 x D / Dynamic 20 x D

Structure and technical specifications

| Fiber Count |

Nominal Diameler (mm) |

Nominal Weight (kg/km) |

Max Fibers Per Tube |

Allowable Tensile Load(N) (Short term/long term) |

Allowable Crush Resistance(N/10cm) (Short term/long term) |

|

| 12-Fiber Ribbon | 12~48 | 13.5 | 178 | 4 | 1500/600 | 1000/300 |

| 60~72 | 13.9 | 189 | 6 | |||

| 84~96 | 14.6 | 203 | 8 | |||

| 108~144 | 15.9 | 230 | 12 | |||

| 156~216 | 18.9 | 310 | 18 | |||

| 24-Fiber Ribbon | 240~288 | 20.0 | 350 | 12 | 3000/600 | 1000/300 |

| 312~432 | 21.4 | 376 | 18 |